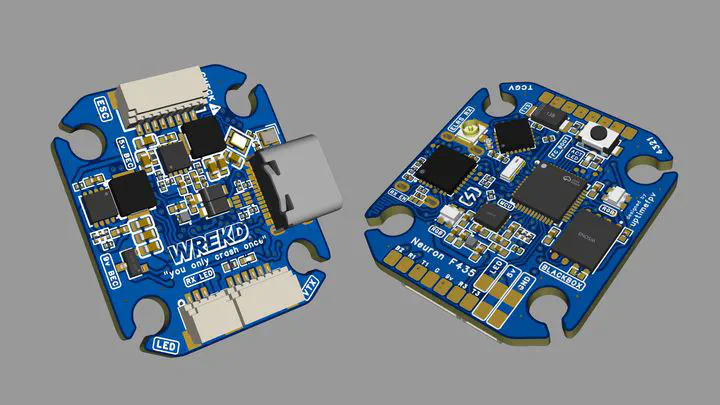

Neuron FC: Dense flight controller and RF system for drones

The Neuron FC is my answer to the challenges of building modern compact racing drones with the pricing of tariffs on chinese components, aiming to offer a single flight controller with high-end features and an integrated RF receiver that will be assembled in the USA while leveraging less expensive alternatives to commonly used ICs.

Why?

When preparing for a new drone racing season, I often find myself building 6-8 new drones from scratch, and they all use small and lightweight airframes that are difficult to build in without specialized flight controllers that integrate multiple other components onto one board. Almost all of said popular flight controllers are designed and assembled by Chinese companies, meaning the tariffs in early 2025 had an especially potent impact on their costs. Most of those flight controllers are also designed for a general market, meaning that they are loaded with features and use parts that are completely unnecessary for 50% of custom drones. With all of these issues in mind, I decided to go ahead and design my own.

Design & Hardware Architecture

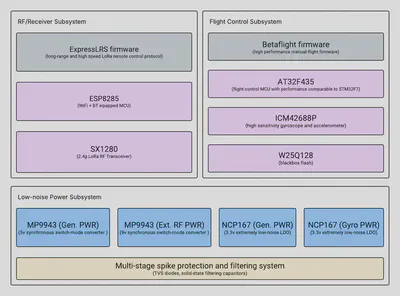

The biggest concerns with the design of this board were the cost of critical components (primarily the microcontroller and gyroscope), choosing low noise voltage regulation circuitry, and squeezing all of these features into a small form factor. The STM32F722 microcontroller that is normally used was switched with the Artery AT32F4, which performs similarly or better at 50% lower cost. While I initially would have preferred to use the MPU6000, the TDK ICM42688P ended up costing much less and offered significantly better performance with a proper design.

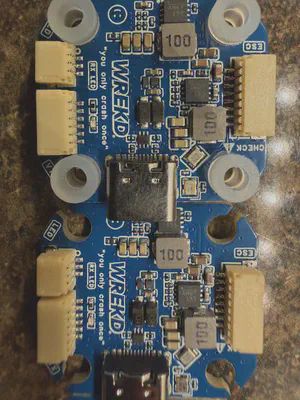

To make sure the ICM gyro outputs as clean of data as possible, I used a multi-stage power filtering architecture (4x regulators in two stages with a high-voltage TVS diode and large solid-state MLCC caps) with a dedicated extremely low-noise LDO (Low Dropout, 85dB @ 1kHz) regulator to ensure the gyro is isolated from the rest of the noisy components. The gyro is also surrounded closely by X5R ceramic capacitors with low trace distance to the LDO, and has a 4 layers of ground plane underneath it with no high speed signals crossing its footprint to ensure that there is no noise coupling. This flight controller is also one of only a few to use the external clock synchronization feature of the ICM42688P, which allows for more accurate and stable readings in newer flight control firmware versions.

In the upper left corner of the board, there is a complete ExpressLRS receiver with a SX1280 LoRa Transceiver, which allows for receiving a control signal at 1kHz update rate and telemetry data transmission at 250hz over the 2.4GHz band through an external U.FL antenna. The receiver also has WiFi through an onboard PCB antenna, allowing it to connect to a known network for remote configuration and firmware updates, or act as a hotspot if no known network is available.

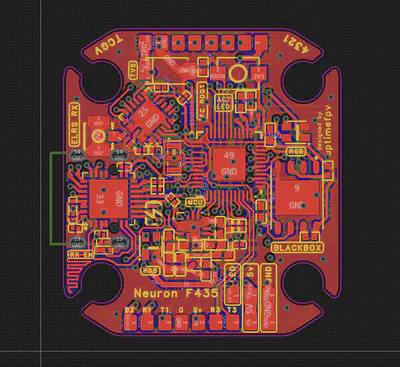

With the critical functionality out of the way, I worked through a minimalistic pad and connector layout that offers all of the neccesary features without taking up too much board area. Along with flight controller, receiver, and all of the power circuitry, this board also includes a 16MB flash memory chip for data logging and multiple addressable RGB LEDs for night operation and to act as status indicators. All of the board design was completed in KiCad and LCEDA based on the assembly capabilities of JLCPCB. The manual routing process was extremely difficult, requiring very careful placement of components and vias to make sure that it could be completed at all, requiring a lot of trial and error to get right. Near the center of the PCB, there is not enough extra area to add a single additional via, this PCB is almost as dense as possible.

Manufacturing

After the design process was done and passed the design rules check, I used industry standard DFM (design for manufacturability) techniques to ensure that the PCB could be produced, changing some component placement in the hopes of being able to perform PnP assembly myself in the future. For now, the entire board is manufactured and assembled by JLCPCB.

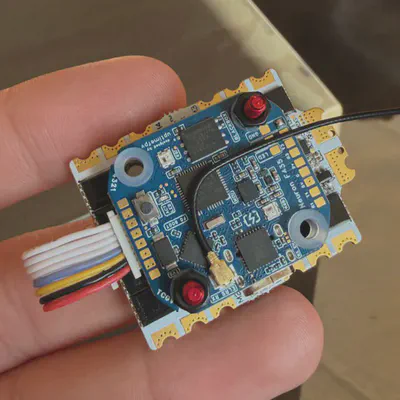

After a significant amount of testing and two rounds of prototypes, the board is completely functional and in the air running stable firmware. Considering the recent FCC sanctions on drone components and tariffs, my next challenge will be working with US manufacturers to produce these flight controllers in-country and potentially sell them through WREKD Co.

More Information

If you are curious about this project, keep checking back here for updates!

The board itself is not open source, but the source code for the firmware is available on GitHub, and some CAD may eventually be released.